myFlashCar

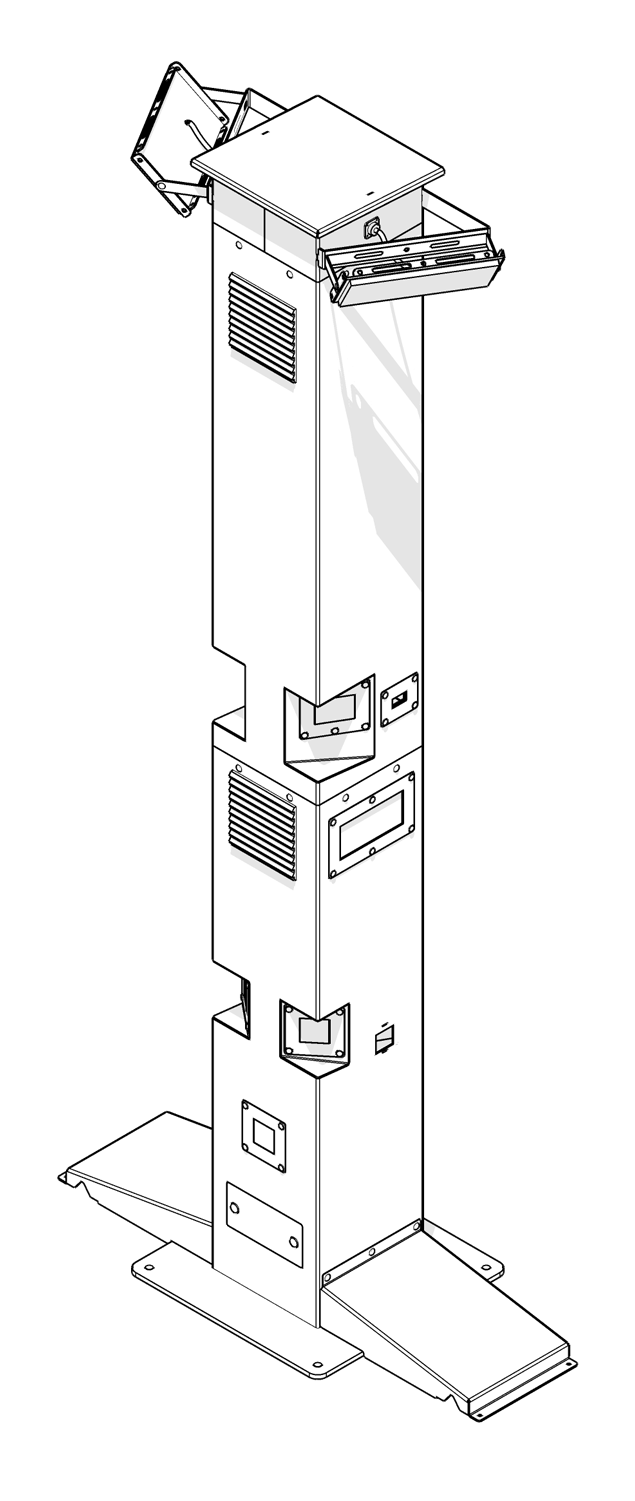

The all-in-one vehicle inspection pillar

all-inclusive rental

myFlashCar is composed of a set of 2 columns with automatic triggering and shooting, and fully equipped for high-quality inspection and photography:

In one single passage, the vehicle is identified and videos are made and analysed to create:

myFlashCar full presentation

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

myFlashCar client showcase

In one single passage, the vehicle is filmed from all angles and the created videos are analysed by the AI to automatically detect damages on the bodywork.

A damage report is generated, with details on all the identified damages.

Data is then synchronised with specialised software and other damage assessment solutions via API.

After AI imagery analysis and bodywork damage detection, a complete and detailed report is automatically generated, listing all the damages in details:

Using the videos made for the inspection, the key angles are automatically extracted and enhanced by the AI, with the option to completely replace the background.

It is also possible to add complementary imagery:

myFlashCar is a modular solution, designed to be flexible and adaptable. It allows for the integration of additional or interchangeable physical modules as well as customizable software modules, enabling you to tailor the system to meet your specific needs.

Modules dedicated to specific automotive activities

Easy to install, directly at the reception of the after-sales, the myFlashCar solution will greatly simplify in advance the required steps in the workshop.

Manage the vehicle health check of your entire fleet with a tailor-made myFlashCar solution that will meets demands at a higher scale.

The Check-in/Check-out feature allows for a precise comparison of a vehicle before and after its rental, thus drastically reducing inspection time and potential disputes.

The Check-in/Check-out feature allows for a precise comparison of a vehicle before and after it has been parked, thus drastically reducing inspection time and potential disputes.

Since 2016, Seestems keeps looking and developing new automated ways to make vehicle marketing and inspection quick and easy, while always having quality and reliability as top priorities.

From big automated car studios to AI-powered mobile apps, Seestems has kept the best of both worlds to create the compact myFlashCar pillars.

The integration of AI into Seestems' solutions has unlocked new possibilities and opportunities.

Leveraging this innovation, Seestems developed its own AI system and routines, meticulously designed to deliver superior-quality imagery and perform precise, accurate analysis while automatically generating efficient VHC reports.